Virtual Prototyping, CAD & Manufacturing

Sports Bumper

Manufacturing Referral

When Bo was referred to us, he had been manufacturing his product in the United States for a year and was considering manufacturing overseas. His production costs were simply too high, leaving him very little profit for the enormous amount of time and work he was investing in his product.

Manufacturing Estimate

After the non-disclosure agreements were exchanged, the design details were provided so that we could we provide him with competitive quotes for manufacturing his product overseas. While the client was very pleased that the estimate would save him a significant amount when compared with his current manufacturing costs, he still wanted to explore options for reducing costs while still manufacturing his product in the United States.

After further research, Bo chose a manufacturer who quoted very competitive prices and told him that everything would be done in the United States. We cheerfully wished Bo success with his new manufacturing partner. 6 weeks later, Bo came back and contracted us to assist him with the overseas manufacturing of his product. Apparently, the things he had been told by the company about manufacturing everything in the United States were untrue. Naturally, he was concerned about committing any further.

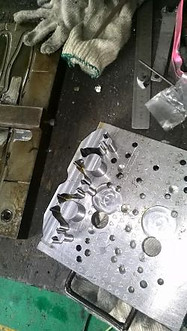

Mold – Tooling – Product Samples

The next step was to make the tools necessary to manufacture Bo's product. The tooling was ordered and the injection mold was completed a month later. The next step was to make parts from the mold to make sure they were satisfactory.

Bo wanted to perform some test markets and asked for samples to be made in several different durometers (hardness of rubber) and colors. Unfortunately, due to a variety of factors, the first parts did not release well from the mold and were defective. This happens. After a week of additional research we provided Bo with several options and made another round of samples (at no additional cost) based on his decision.

The 2nd batch of samples appeared to be satisfactory and were shipped to the client for inspection and approval. The client was satisfied with the results and then paid the balance of the tooling.

Manufacturing & Packaging Run

The first production run was started with a down payment of half the total amount. About 4 weeks later, the first production run was completed, packaged and shipped to the client. The client was pleased with the product he received. We also designed, manufactured and shipped the the retail packaging for his product. This portion of our service was shipped separately because the client only wanted to use the packaging on units that were being sold through distributors and retailers, allowing him to avoid the extra cost for online/consumer direct sales.

Testimonial

“Working with DCP manufacturing team has been a real pleasure. Even though my process was met with some hurdles, everything was managed well and with the utmost professionalism. They were very patient with me and my questions/concerns with manufacturing overseas. And when things didn’t work out according to plan, they were available to talk and assure me that everything will work out, which it did. I would recommend DCP's services to any of my friends and have done so already.”

Bo P. - CO

Tooling

Manufacturing Update

Bo now has 3 products in production

with Dirt Cheap Prototypes' Assistance

Product Development

-

Engineering & Design

-

CAD

-

Physical Prototyping

-

Manufacturing Assistance

-

Focus Groups

Digital Media

-

Virtual Prototyping

-

Website Design

-

Photography

-

Video Production

* - Dirt Cheap Prototypes does not provide patent or marketing services